CNC Machining Applications in Automotive Parts: Processes & Benefits

2025-07-25 14:58:02

Source:cfz

🚗 How CNC Machining Powers Automotive Parts Manufacturing

The automotive industry demands precision, durability, and scalability—qualities that CNC machining consistently delivers. From safety-critical components to structural chassis parts, CNC processes are central to modern vehicle production.

In this article, we explore the CNC machining applications in various automotive parts, the specific manufacturing processes used, and why CNC is the go-to method for high-quality, mass-customized production.

🧩 Automotive Parts and Their CNC Machining Processes

1. Control Arm (Triangular Wishbone / Suspension Arm)

Application: Connects the vehicle frame to the wheel hub and manages wheel motion.

Machining Process:

- Milling for creating the arm contour

- Drilling for mounting holes

- CNC turning for bushing seats

- Material: Steel or aluminum alloys

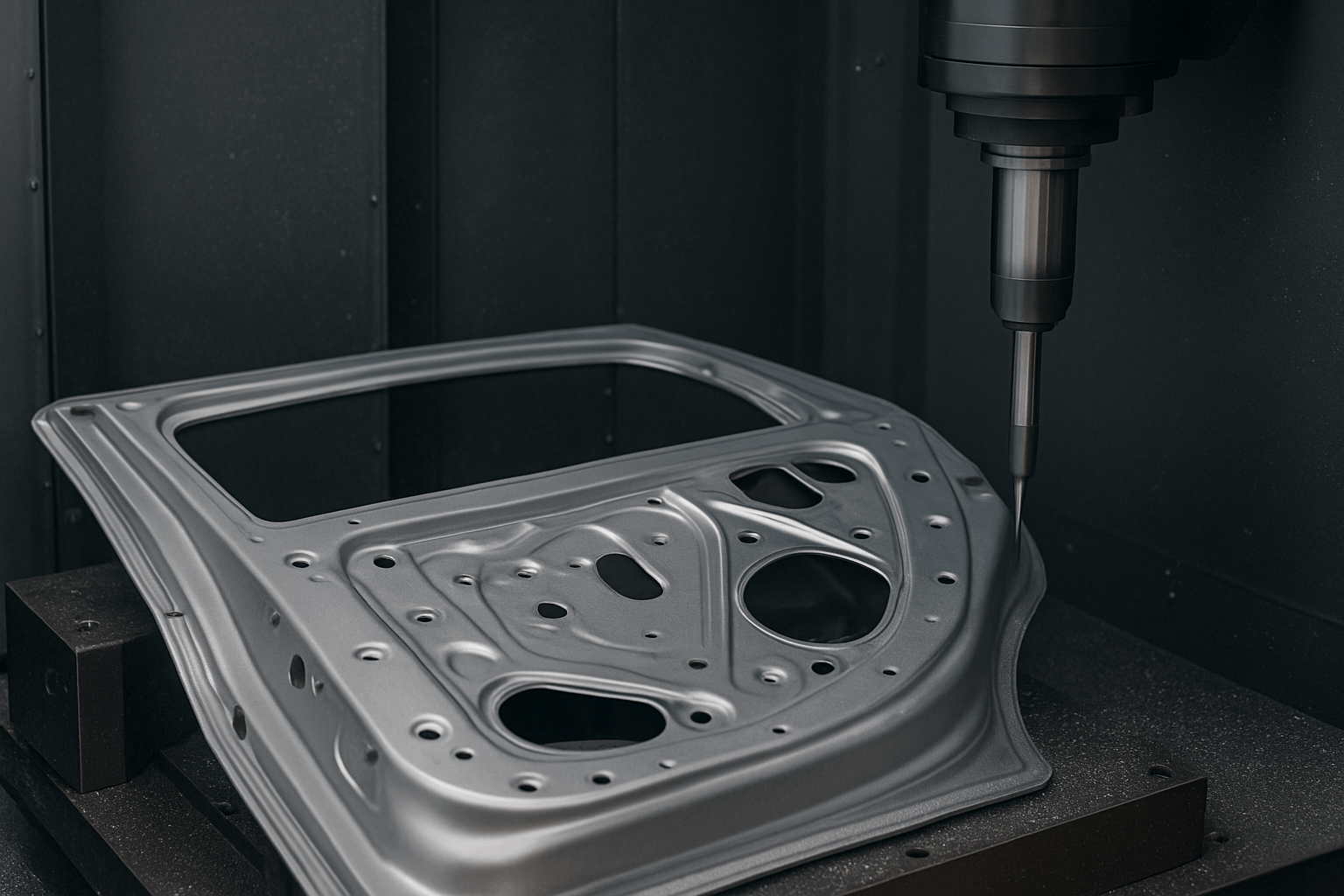

2. Car Door ComponentsApplication: Provides structural integrity, supports window and locking systems.

Machining Process:- Stamping & CNC milling for inner reinforcement frames

- Laser cutting for complex shapes

- Surface grinding for flush alignment

- Material: Sheet metal, aluminum alloy

3. Subframe Lower Plate (Subframe Underbody Plate)Application: Distributes chassis load, enhances structural stability.

Machining Process:- Precision milling for flatness

- Welding with CNC-prepped joints

- Thread tapping for mounting interfaces

- Material: High-strength steel or cast aluminum

4. Chassis Bracket / Chassis Suspension MountApplication: Holds suspension and steering systems in place.

Machining Process:- 5-axis CNC machining for complex geometry

- Hole drilling for bolting points

- Surface anodizing for corrosion resistance

- Material: Forged aluminum or structural steel

5. Chassis Crossmember (Chassis Bridge)Application: Links left and right parts of the chassis, absorbs torque.

Machining Process:- CNC plasma cutting

- CNC milling for interface alignment

- Thread forming

- Material: High-strength tubular steel

6. Crash Beam / Impact BarApplication: Absorbs energy during a collision, protects cabin.

Machining Process:- 3D CNC bending of high-tensile tubing

- Slot milling for mounting brackets

- Powder coating for durability

- Material: Ultra-high-strength steel or aluminum

7. Reinforcement PlateApplication: Enhances local rigidity of the vehicle body.

Machining Process:- CNC punching for bolt patterns

- Flat-bed laser cutting

- Surface deburring

- Material: Cold-rolled steel

8. Car JackApplication: Lifting tool for tire change or vehicle repair.

Machining Process:- Lathe turning for screw threads

- CNC milling for base and arm profiles

- Heat treatment for load-bearing strength

- Material: Tool steel or ductile iron

9. Sunroof Frame and ComponentsApplication: Supports glass and drive mechanism of the sunroof.

Machining Process:- Precision CNC milling for the guide rail

- Micro-drilling for fastener holes

- Anodizing for weather resistance

- Material: Lightweight aluminum alloy or reinforced plastic

🛠️ Why CNC Machining is Ideal for Automotive Manufacturing- Precision Tolerances: Up to ±0.001 mm, perfect for safety-critical parts

- Repeatability: Consistent quality across high volumes

- Material Flexibility: From aluminum and steel to engineering plastics

- Complex Geometry: Multi-axis CNC handles intricate designs easily

- Fast Turnaround: Ideal for prototyping and production

- Cost-Efficiency: Optimized programming reduces waste and rework

📩 Get Custom CNC Parts for Your Automotive ProjectsAt Wanchuangda Technology, we specialize in high-precision CNC machining for the automotive industry. Whether you’re developing safety systems, chassis parts, or prototyping next-gen vehicles, we’re ready to meet your needs.

👉 Contact us today for a free quote or consultation.